in the present industrial landscape, the stress is mounting. organizations face the dual problem of optimizing operational performance while at the same time demonstrating a tangible motivation to environmental sustainability. typically, the main target falls on massive-scale initiatives – renewable Electrical power adoption, squander reduction plans, or offer chain optimization. having said that, sizeable gains can normally be present in the small print, specifically during the components that variety the backbone of electrical and Digital units. Cable crimp connectors, Particularly Individuals from trusted copper connector brands, play a significant position. selecting connectors dependent exclusively on First Charge can lead to a cascade of hidden charges and environmental burdens down the line. Conversely, prioritizing durability isn't really almost longevity; it is a strategic determination that directly translates into minimized resource usage, reduce upkeep expenses, and Improved operational reliability – a gain-gain for both equally the stability sheet and the World. This exploration delves into why sturdy cable connectors are An important component of contemporary, sustainable industrial tactics.

Table of contents:

substance Matters: the muse of Longevity

Engineered for Endurance: The job of Structural style and design

Extending the Lifecycle: an extended-phrase Perspective on financial savings

source Conservation: additional than simply steel

providing Enduring price: Gains over the Chain

product Matters: The Foundation of Longevity

The lifespan and reliability of a cable connector get started at probably the most basic degree: the material it's constructed from. the selection of material dictates its resistance to environmental stressors, its structural integrity with time, and eventually, how routinely it will require replacement.

the strength of High-energy Aluminum: While many metals are Utilized in connector manufacturing, higher-toughness aluminum alloys provide compelling strengths in unique demanding programs. Notably, their inherent resistance to corrosion is a substantial variable. In environments characterized by large humidity, salinity (coastal or maritime programs), or exposure to industrial chemical substances, connectors made out of inferior products can quickly succumb to rust and degradation. This corrosion not only compromises the physical framework and also degrades electrical overall performance, leading to prospective failures and mandatory substitution. substantial-high-quality aluminum alloys, nevertheless, sort a protecting oxide layer, enabling them to withstand these harsh situations for prolonged durations. This will make them exceptionally effectively-fitted to long-time period outdoor installations, renewable energy infrastructure, and tough industrial configurations in which longevity is paramount.

Structural Stability and ageing: past corrosion, the inherent steadiness in the chosen material plays a vital purpose in combating structural getting old. Connectors are subjected to mechanical tension in the course of installation (crimping) and throughout their operational lifetime on account of vibration, temperature fluctuations, and Actual physical handling. large-quality products, engineered for stability, resist deformation, micro-fractures, and embrittlement after some time. This ensures the connector maintains its structural integrity and clamping pressure, blocking intermittent connections or complete failures that necessitate untimely substitute.

Comparative Lifespan Evaluation: When compared to some typically applied components like basic steel or sure grades of brass, carefully chosen and addressed significant-energy aluminum alloys can present top-quality longevity, notably in corrosive environments. While copper is an excellent conductor frequently popular (quite a few look for a responsible Copper connector provider for this reason), specialised aluminum alloys can offer a greater equilibrium of sturdiness, pounds, and corrosion resistance for particular structural and environmental problems. The decision isn't always about conductivity on your own, nevertheless the holistic functionality over the complete lifecycle. picking out resources specifically for their endurance features demonstrates a further commitment to cutting down the substitution cycle, that's inherently much more sustainable. much less Repeated substitute indicates fewer mining, refining, and processing of Uncooked elements above the operational lifespan in the products or installation.

Engineered for Endurance: The purpose of Structural style and design

Material selection lays the groundwork, but complex structural layout transforms prospective longevity into dependable performance. how a connector is engineered specifically impacts its power to sort and manage a protected, small-resistance link, minimizing the need for servicing and substitution.

Precision Interfaces (DIN expectations): Adherence to established expectations, for example DIN seventy four for certain connector forms, signifies a motivation to precision engineering. These criteria dictate critical dimensions and tolerances for that connector's interface. A exactly made interface guarantees a cosy, safe match While using the corresponding terminal or conductor. This higher diploma of in good shape minimizes the opportunity for micro-movements brought on by vibration or thermal cycling, which may lead to loosening, elevated contact resistance, heat generation (hot places), and likely perilous electrical arcing. A relationship that stays restricted requires much less Regular inspection and removes failures due to lousy mechanical in shape, thereby extending its helpful everyday living and minimizing involved upkeep labor.

Mechanically Robust Crimping Zones: The crimp location is wherever the connector bodily joins the cable conductor. The design of this zone is significant for extended-term trustworthiness. Connectors engineered with large mechanical toughness in the crimping barrel be certain a strong, gas-restricted connection when properly crimped. This sturdy design withstands the significant forces used throughout set up without having cracking or deforming excessively. More importantly, it maintains consistent strain to the conductor strands with time, avoiding strand breakage, click here pull-out, or even the ingress of moisture and contaminants that can degrade the connection. a powerful, dependable crimp is basic to avoiding electrical failures and the following have to have for connector substitute.

Adaptability and Waste Reduction: Connectors created with wide adaptability for numerous cable dimensions or kinds in just a specified selection present another refined sustainability edge. utilizing a connector that can reliably accommodate a little unique conductor diameters or insulation thicknesses (within just its rated ability) minimizes the likelihood of making use of an improperly sized part, which can result in bad connections or squandered parts. Furthermore, it simplifies stock management for big jobs, minimizing the amount of SKUs necessary and reducing probable obsolescence or waste because of specification adjustments.

Extending the Lifecycle: an extended-phrase viewpoint on Savings

The true worth of a long lasting connector emerges when considered throughout the lens of its full lifecycle. Focusing only about the upfront obtain value ignores the significant downstream fees connected with Recurrent replacements.

Comparing Replacement Cycles: take into account a typical industrial software. regular, reduced-high-quality connectors could have to have inspection and possible replacement just about every several years, or a lot more routinely in harsh environments. In distinction, a large-toughness connector, created with superior elements and layout, could realistically very last considerably for a longer time, Maybe matching the lifespan in the machines by itself. Quantifying this difference – evaluating the standard replacement cycle of ordinary connectors compared to the prolonged lifespan of quality kinds – reveals a compelling economic argument.

Cumulative Expense personal savings (Beyond the section): Every single substitute celebration incurs expenditures significantly exceeding the price of the connector by itself. These contain:

oLabor: experts' time for diagnostics, removal, and set up.

oDowntime: misplaced output or operational capacity although repairs are created.

oLogistics: Transportation fees for new elements and most likely for staff.

oMaterials: the expense of the alternative connector and any linked consumables.

When multiplied about hundreds or thousands of connection details in a big facility or job, and repeated above various substitute cycles averted, the cumulative personal savings turn into considerable. This Total price of possession (TCO) viewpoint clearly favors resilient components.

Reducing Rework and challenge Delays: In important engineering or building tasks, connector failures for the duration of commissioning or early Procedure may lead to expensive rework and major delays. employing connectors noted for their trustworthiness from your outset minimizes this hazard. picture the impact on a renewable Electricity farm or even a manufacturing plant rollout if dozens of connections are unsuccessful prematurely – the troubleshooting exertion and agenda disruption can dwarf the First Expense variation of applying increased-good quality parts. toughness interprets straight into challenge certainty and dependability.

source Conservation: extra Than Just steel

The environmental benefits of tough connectors extend over and above basically working with fewer Uncooked materials with time. lowering the alternative frequency triggers a optimistic cascade influence throughout numerous useful resource streams.

lowered Manufacturing Footprint: Every connector produced needs energy for extraction, processing, manufacturing, and finishing. less replacements indicate noticeably considerably less cumulative Vitality usage and less involved emissions (greenhouse gases, pollutants) through the manufacturing system more than the program's lifetime. It also signifies less scrap metal created in the course of production and disposal.

Minimized Packaging squander: Connectors are generally packaged for protection and identification. While necessary, packaging contributes to waste streams. Halving the amount of replacements desired directly halves the affiliated packaging squander (cardboard, plastic) created above the operational period.

reduce Transportation Emissions: Fewer replacement cycles specifically translate into less transportation runs required to deliver new components to web page, Specially vital for big-scale industrial projects or geographically dispersed infrastructure. This reduction in logistics activity lowers the general carbon footprint linked to routine maintenance and repairs.

Increased Energy Efficiency: Poor or degrading connections exhibit bigger electrical resistance. This resistance brings about Power loss in the shape of heat (I²R losses) and can result in voltage drops, possibly impacting equipment performance. Stable, very low-resistance connections preserved above lengthy periods due to long lasting connectors lead to Over-all process Electricity performance, cutting down operational Electricity squander.

offering Enduring Value: Positive aspects throughout the Chain

The adoption of resilient cable connectors delivers tangible value not simply environmentally, but additionally strategically to companies and their prospects.

lessen upkeep Burden for Bulk people: For Original devices producers (OEMs) or program integrators managing significant fleets of equipment or considerable installations, extending the upkeep cycle of elements like connectors right decreases their ongoing assistance and warranty expenses. This translates into enhanced profitability and possibly additional aggressive provider offerings.

Alignment with Sustainability Trends: ever more, industries are facing regulatory pressure and sector need for environmentally dependable goods and operations. Specifying and making use of durable elements that limit waste aligns with corporate sustainability targets and satisfies the rising expectation for eco-certified or environmentally acutely aware industrial components. providers are actively trying to get suppliers, including attempting to find a liable Copper connector maker or providers of other resilient material alternate options, who will help these initiatives.

Improved manufacturer track record: organizations that prioritize large-top quality, resilient parts sign a commitment to dependability and long-time period price. picking suppliers noted for their strong and environmentally thought of merchandise can boost the top-person's manufacturer picture, positioning them as liable and high quality-focused entities in just their unique markets. It demonstrates a dedication that goes further than the surface area stage, embedding sustainability in the incredibly fabric of their functions.

The standard cable crimp connector, typically overlooked, gives sizeable financial and environmental Positive aspects. concentrating further than the Preliminary order selling price highlights the importance of longevity for prolonged-expression efficiency and sustainability. selecting connectors made with significant-power components like aluminum, precision engineering, and a center on lifecycle efficiency can dramatically lessen alternative frequency. This lowers total possession expenditures by financial savings in labor, downtime, and logistics, although conserving means, minimizing squander, and reducing the carbon footprint tied to manufacturing and transportation.acquiring these Gains needs partnering with companies who prioritize longevity and source performance. firms like N.I.U ELEC structure Cable Crimp Connectors with durability as a Main theory, delivering solutions that boost trustworthiness whilst supporting environmental ambitions. picking durable connectors isn’t just an alternative—it’s a strategic investment in building a more sustainable potential.

Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Amanda Bearse Then & Now!

Amanda Bearse Then & Now! Julia Stiles Then & Now!

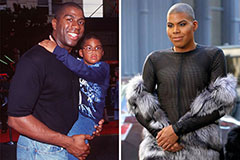

Julia Stiles Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now! The Olsen Twins Then & Now!

The Olsen Twins Then & Now!